Customer Drawing

Dye Making (Tools Making)

Wax Injection

WAX PATTERN PROCESSING

WAX ASSEMBLY

SHELL CERAMIC COATING

DE-WAXING

SHELL BAKING

METAL POURING

CLEANING & CASTING REMOVAL

CUTTING AND POLISHING

Final Inspection & Dispatch

Customer Drawing

Dye Making (Tools Making)

Wax Injection

WAX PATTERN PROCESSING

Wax in semi-liquid form is injected in Dies (Pattern/Tools) to produce replica of desired castings. Semi automatic hydraulic press is used to produce wax patterns. All the wax patterns are 100% checked visually and dimensionally. Wax patterns are assembled to wax runner using wax gates and then wax runner is attached to wax pouring cup to make a cluster or tree.

WAX ASSEMBLY

Wax patterns are assembled to wax runner using wax gates and then wax runner is attached to wax pouring cup to make a cluster or tree

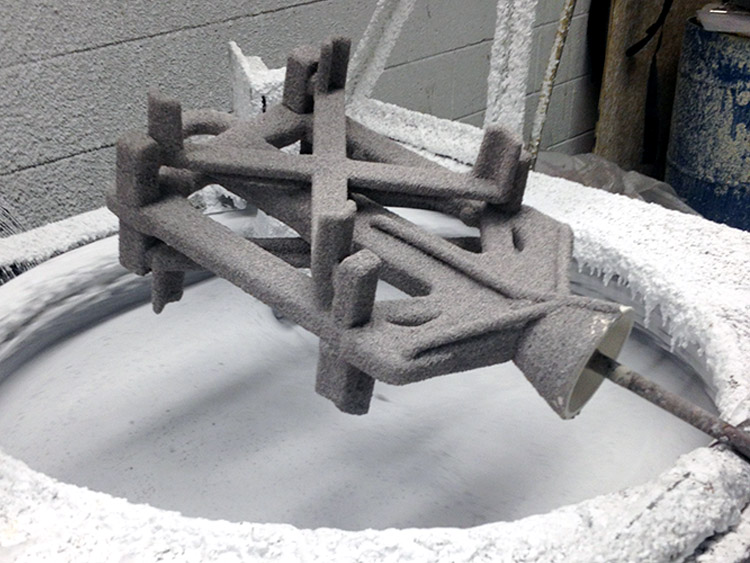

SHELL CERAMIC COATING

The wax assembly is coated with a ceramic shell by repeated dipping in ceramic slurries and alternately in dry beds of sand and clays, heavy or thick sections are features of any part, additional coating are to give added strength to the shell. Thus eliminating bulging or distortion of the casting to complete this stage, the ceramic shell is heated under pressure in an autoclave and the wax removed by melting, leaving a hollow shell.

DE-WAXING

SHELL BAKING

After wax is removed, a ceramic mold is then heated to 1800 degrees Fahrenheit in a preheat oven. The heating of the mold fuses the ceramic particles so the mold can withstand the pressure and temperature of the upcoming molten metal. It also removes all traces of organic materials. The preheating of the shell improves the ability to cast fine detail and improves the feed of liquid metal to compensate for volumetric shrinkage.

METAL POURING

Molten metal is poured into the pre-heated molds. Standard pouring temperatures are approximately 3,000 degrees Fahrenheit for steel. With every melt pour, the heat’s chemicals are analyzed spectrographically to assure compliance with customer specifications. The process of investment casting allows customers to choose from a wide variety of alloys since any alloy can be investment cast economically.

CLEANING & CASTING REMOVAL

After the metal-filled mold is cooled, the ceramic shell is removed with high-pressure jets of water.

After the shell is removed and the metal parts are exposed, the components need to be removed from the metal sprue. MARUTI INV Steel Cast uses our proprietary processes to safely remove the components.

CUTTING AND POLISHING

" Maruti Inv Steel Cast "

Plot No:401, Road No.10,

Kathwada G.I.D.C.,

Ahmedabad,Gujarat, India.

Email: info@marutisteelcasting.com

Email: marutisteelcast@gmail.com

Mobile: +91 98251 69267

" Maruti Inv Steel Cast "

Plot No:401, Road No.10,

Kathwada G.I.D.C.,

Ahmedabad,Gujarat, India.

Email: info@marutisteelcasting.com

Email: marutisteelcast@gmail.com

Mobile: +91 98251 69267