Investment Casting Benefits

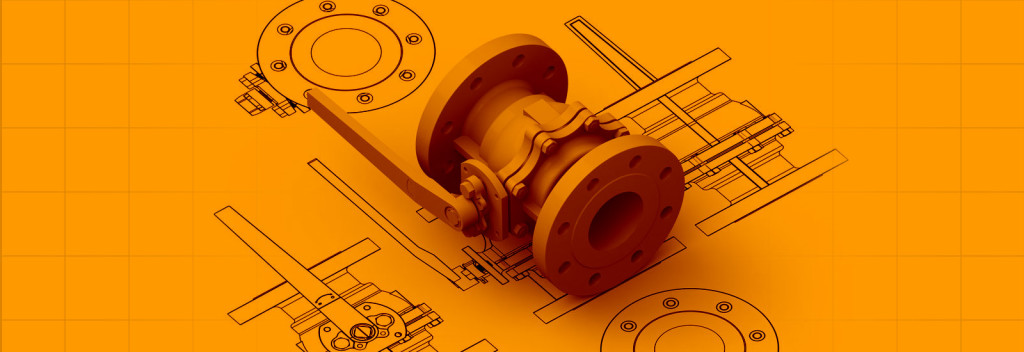

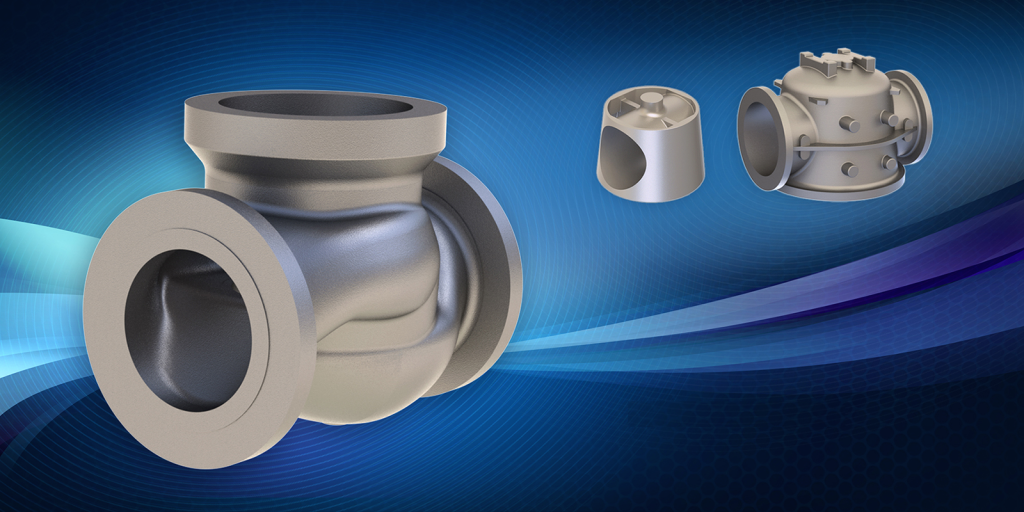

Investment Casting offers greater design freedom (complex intricate shapes easily as well as assemblies cast as one part), greater investment casting alloy selection to best meet your investment casting application), improved surface finishes and a greater opportunity for cost and weight reduction. Also known as lost wax Investment Casting, investment Castings will enhance the design and the performance of your mechanical components. Consolidated Casting offers Investment Castings to precision tolerances of +/- .005 inch per inch and to machined like surfaces of 125 RMS.

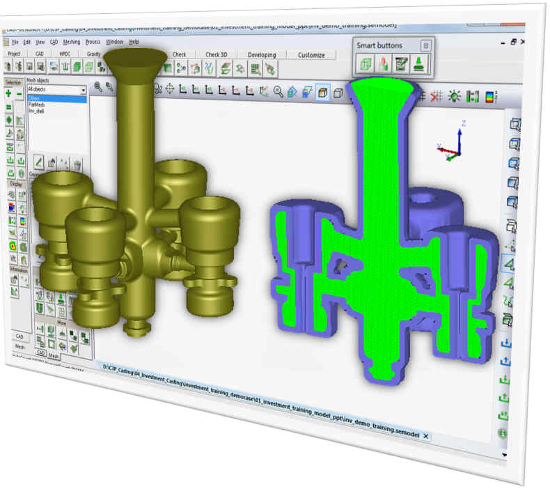

Investment Casting – Design

The main stages of the Lost wax Process are the following…

With the Lost Wax Method we can cast in steel with the same surface finish and precision as Die Casting can do with Aluminium and Magnesium Alloys.

Since we are using a much cheaper Die to cast highly complicated parts in a shorter series. we can claim that the Investment Castings Process can cast the most complicated parts at a cheaper rate.

But, we have to follow the casting Rules for Investment Casting, which do not tally with Traditional Casting Rules

" Maruti Inv Steel Cast "

Plot No:401, Road No.10,

Kathwada G.I.D.C.,

Ahmedabad,Gujarat, India.

Email: info@marutisteelcasting.com

Email: marutisteelcast@gmail.com

Mobile: +91 98251 69267

" Maruti Inv Steel Cast "

Plot No:401, Road No.10,

Kathwada G.I.D.C.,

Ahmedabad,Gujarat, India.

Email: info@marutisteelcasting.com

Email: marutisteelcast@gmail.com

Mobile: +91 98251 69267